Ultimate stability and accuracy with Rainford Precision’s KERN machine

“You don’t put cheap tools on an expensive machine!” Do you want the ultimate in accuracy,…

The trend of more manufacturers entering the ‘micro-machining’ sphere was evident at MACH 2024 as the industry experts Rainford Precision celebrated an exceptionally successful show. As the outright leaders in small and micro component machining solutions, the level of enquiries was unprecedented for everything from specialist and micro cutting tools to the Kern micron precision 5-axis machining centre and the Finepart micro abrasive waterjet machining solution.

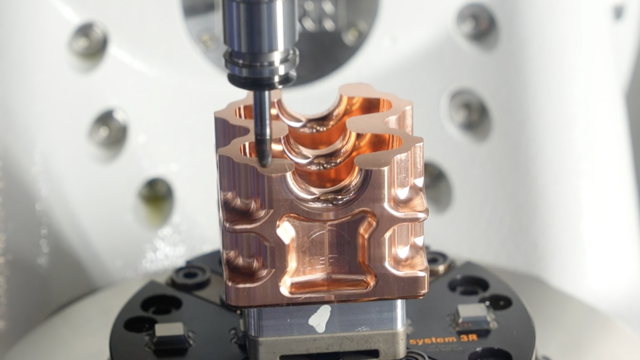

The Kern Micro HD 5-axis machining centre made its UK exhibition premiere and this machine certainly stole the show. Kern is renowned for its unparalleled levels of precision and at MACH, the Micro HD machine that comfortably achieves precision and repeatability levels of +/-1micron on the workpiece in the correct temperature controlled environment during 5-axis machining demonstrated its incredible speed, precision and productivity. The Kern Micro HD was one of the very few in the elite echelon of brands demonstrating this level of precision at MACH. As Rainford Precision’s Managing Director, Miles Evans comments: “Kern is a brand synonymous with precision and performance that is the benchmark of the industry, and at MACH, the crowds were like ‘bees around a honeypot.’ Probably the only machine at MACH capable of achieving precision and repeatability levels of +/-1micron, we had some very serious enquiries from manufacturers that are losing production hours and scrapping parts due to machines unable to meet the ever tighter tolerances the market requires. Not all manufacturers need this level of precision but for those teetering on the edge of high-precision manufacturing – the Kern is a standout performer and this was evident at MACH.”

Also drawing a high level of interest at MACH was the Finepart ‘micro’ precision waterjet cutting machine. With a positional accuracy of +/-2.5microns and a repeatability of +/-2microns with a typical cutting tolerance of +/-10 microns, this machine attracted a significantly high number of serious enquiries.

Acknowledged as a specialist in world-renowned cutting tool solutions that are capable of cutting the smallest, hardest and most challenging of materials that are beyond the realms of most manufacturers, Rainford Precision presented a suite of new products from brands such as Union Tool, Louis Bélet, Delmeco, Gloor, HOBE, Osawa, DTS, Iwata, 6C Tools, Hufschmied, Swissceramill and ATOM. The respective partners are industry leaders in the manufacture of drills, end mills, reamers, boring bars, threadmills, slitting saws and more. Commenting on the popularity of these product lines, Miles continues: “We received an impressive number of leads across all our cutting tool brands with the stand-out performers being the new product lines from Union Tool, Louis Bélet and 6C Tools. We had two demos on the Kern machine with the 6C PCD tools and stand visitors were thoroughly impressed by their performance. Likewise, the Hufschmied tools for machining graphite generated a huge amount of interest from stand visitors. Our level of serious enquiries is as high as it has been at any previous MACH show and we are extremely pleased with the potential projects that we have in the pipeline as a result of the show.”

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters