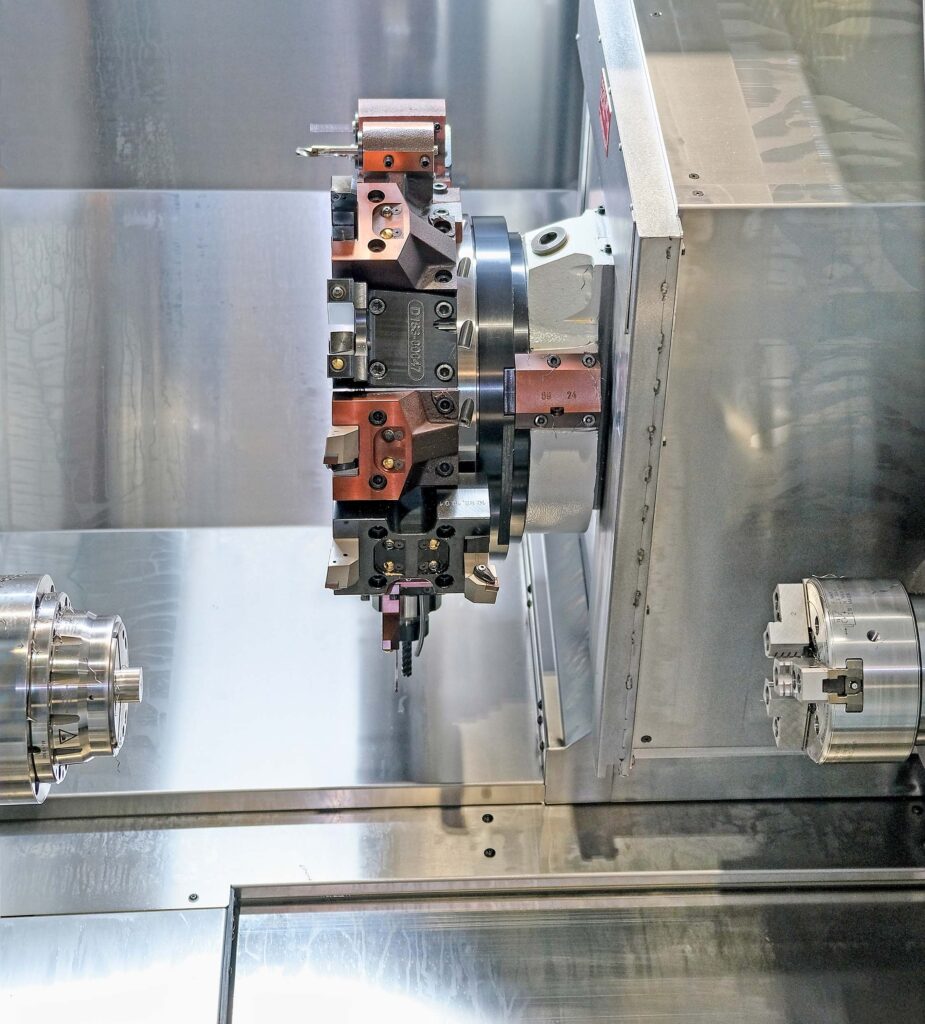

Architectural ironmongery manufacturer Instinct Hardware has recently invested in a host of equipment that includes an Italian-built Biglia bar-fed, twin-spindle lathe with a ± 45 mm Y-axis turret having and 15 driven tools.

Installed in the Stirchley factory where premium quality door knobs and handles, door stops, and accessories are manufactured, the latest turning centre was sourced in May 2024 from the Whitehouse Machine Tools.

The company supplied the machine as a turnkey package with a bar feeding unit and a gantry-type system for unloading components onto a conveyor.

This handling method was chosen to prevent damage to the components’ surface and preserve their aesthetic appearance.

Whitehouse also supplied programs and tooling for producing two key components and their prove-out in Kenilworth, plus comprehensive training.

Instinct Hardware products are either standard catalogue items or manufactured to bespoke designs and have been used in prestigious projects.

These include the ongoing refurbishment of Citibank UK’s London headquarters, Google’s new headquarters in King’s Cross, various London Underground stations, the recent renovation of Wembley Stadium and Liverpool FC’s modern training centre.

Until now, stainless steel has accounted for 80% of production, with the remainder mainly brass and bronze.

However, an increasing amount of aluminium is being processed due to its easy recyclability.

Director Nil Chohan says: “Since we moved to our current premises, we have been increasing our machining capacity to reduce our reliance on subcontractors.

All of our lever handles require a square hole to be broached.

This has always been done separately on a hydraulic press, as before the Biglia B 620 YS was installed, we did not have a rigid enough lathe.”

“We bought the Italian turning centre specifically because it can broach our stainless steel handles, which Whitehouse demonstrated before we committed to the machine.

So, we can now perform all operations in one hit rather than in five or six operations.

It significantly reduces scrap rate by avoiding repeated manual setups and greatly speeds manufacturing time, enabling us to fulfil our promise of a 10 to 14-day order turnaround.”

A case in point is machining a component assembled into a stainless steel, oval-profile, mitred lever handle.

It previously required six machining operations from turning on a 3-axis lathe, milling and drilling on a VMC, broaching on a hydraulic press, further prismatic machining on a different VMC, slotting on yet another VMC and mitring on a bandsaw before welding.

This consumed 15 minutes of machining time plus 10 minutes of handling and setup for each of the five additional operations.

On the Biglia, the part comes off complete in 8.5 minutes, representing an eight-fold time saving, with the added benefit of eliminating work-in-progress and the potential damage to components.

Nil Chohan needed a robust and powerful machine capable of broaching stainless steel, he was impressed by the specification of the B 620 YS, particularly the 30kW direct-drive, liquid-cooled main spindle motor offering 700Nm of torque.

The lathe has boxways in the X and Y axes to promote rigidity and accurate machining, with a linear guide rail in the Z-axis for traverse speed.

He says: “Reputation is hard to establish but even more challenging.

Through hard work and endeavour, we have become a leading European manufacturer of bespoke architectural ironmongery.

Today, our team is committed to continued investment and further developing our range and brand with an increased focus on sustainability of materials and logistics.

We are constantly looking at new machinery like the Biglia to develop and enhance our offering whilst maintaining our passion to continue driving the company and our industry forward.”

Subscribe to the MTDCNC Newsletter

Subscribe to our Newsletter today!

Stay up to date with the latest industry news and events.

Subscribe to the MTDCNC Newsletter

Powerful lathe enables stainless broaching.

0:00 / 0:00