Kyocera SGS

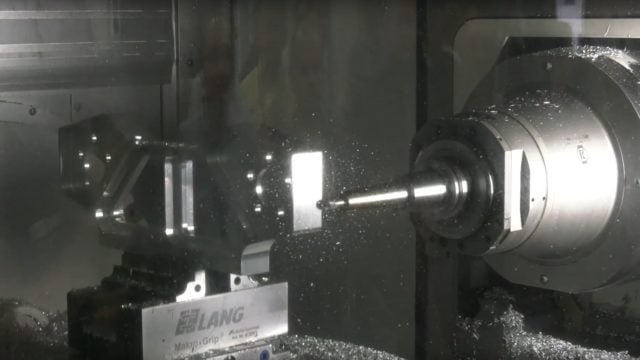

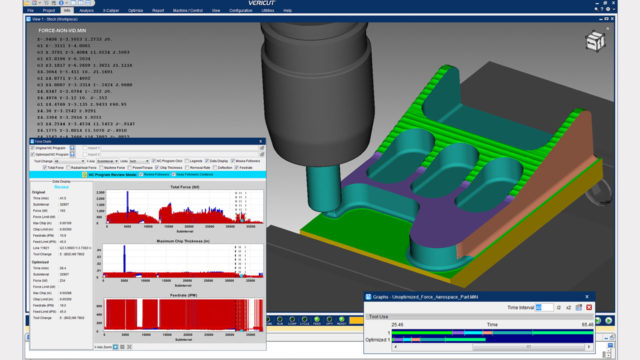

At Kyocera SGS we provide ‘Total Process Innovation’. This requires a team of experienced and capable engineers to look at the whole process, often from ‘outside the box’. Optimisation comes from detailed analysis of every element required, including the machine tool, fixture, toolholder and, of course, the cutting tool. The goals are to reduce time, both the set up and the machining cycle times, and improve quality and process reliability by making the whole sequence robust. Total Process Innovation is usually driven by the customers’ requirements to meet difficult project challenges. These may be based on the materials being machined; tolerance, geometric form and surface finish required; cost savings as the result of process efficiency gains, or often a combination of all these factors. To achieve this Kyocera SGS forms a full ‘turnkey partnership’ with the customer.