Darex 3000I Drill Sharpener

The Darex XT-3000 Drill Sharpener is a workhorse sharpener which can be expanded to meet a…

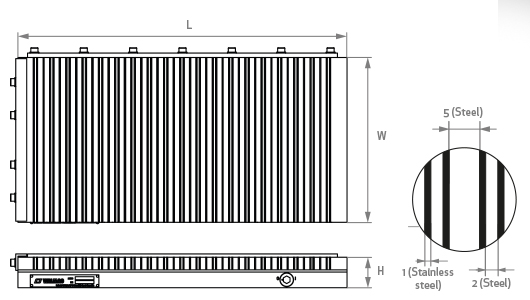

NEODYMAX PERMANENT MAGNETIC CHUCK FOR SURFACE GRINDING

Neodymax ranks among the strongest permanent magnetic chucks in our range. Heavy holding force up to 120 N/cm2 helps clamp the parts during machining efficiently. This is due to the double neodymium magnetic system capable of exerting a high holding force and retaining a low chuck weight. The top plate is made of very durable material and provided with transverse combined poles with a pitch of 5/1/5/1/2/1 mm (steel/stainless steel). Consequently, Neodymax is suitable for workpiece clamping during precise surface grinding when it is no problem to clamp small and thin parts as well as much bigger components. The chuck can also be used for light milling operations. Thanks to its waterproof design, the chuck can be immersed in dielectric liquid during EDM machining. Application: Milling, grinding, EDMTechnology: Permanent Holding force: 120 N/cm2Min. workpiece size: 10 x 10 x 5 mm Poles: Transverse Regrinding limit: 6 mm Pole pitch: 15 mm, further refined 5/1/5/1/2/1 steel/stainless steel

Parameters

Parameters

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters