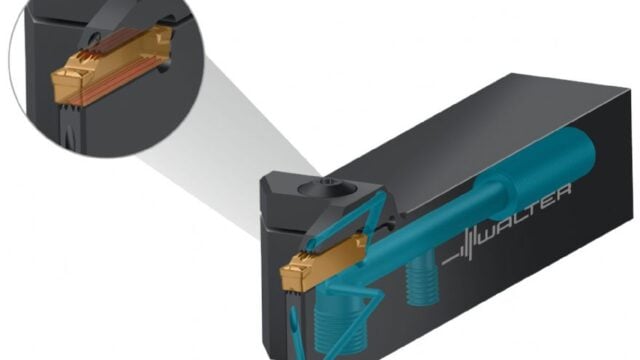

Walter GB Launches Groov·tec GD 5011-P: A New Benchmark in Grooving Systems

Bromsgrove-based Walter GB Ltd has introduced a new cutting-edge platform for parting off, grooving, copy turning,…

Machining specialist Walter is now supplying its products in packaging that is made from up to 95% recycled plastic. Known as PCR, a material that is fully recyclable, this new packaging strategy is an important step in increasing circularity to above 90%, a goal which the Tübingen-based company wants to achieve by 2030.

This is just one of four sustainability targets that Walter has committed to over the next few years. The company has pledged to halve its CO2 emissions to avoid causing any harm to people and to act transparently and ethically – in other words, to always do the right thing.

“We have set ourselves ambitious sustainability targets to meet by 2030, and these affect every area of the company. With the new packaging, we are taking the next logical step on this journey. And that’s not all – our main goal is to be climate-neutral by 2050. It is essential that we take every opportunity to effectively reduce our CO2 emissions. On multiple levels, the PCR packaging plays a part in this,” explains Gerhard Schüßler, Head of Sustainability at Walter.

Minimum impact on the environment and good product protection

Producing the recycled plastic for the new packaging only requires half the energy that is used for new plastic. This is equivalent to a 60-ton decrease in CO2 emissions compared to 2022. What’s more, the use of fossil raw materials is reduced and less energy is required. To cut down on transportation, the next step is to produce the packaging not only in Germany but also everywhere that Walter has distribution centres.

Alongside the sustainability credentials, the new packaging offers benefits to Walter customers too. The recycled material is as robust as new plastic, providing products with optimal protection against corrosion and other damage. In this way, maximum functionality is combined with the best possible product protection and minimum impact on the environment.

The switchover to the new packaging material started in 2023 and the aim is for it to be used as the standard packaging material for 85% of Walter’s products throughout 2024.

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters