Have you seen these dedicated tools for mould and die?

Mould and die can be a complicated sector to work within. Fortunately, Hexagon has a suite…

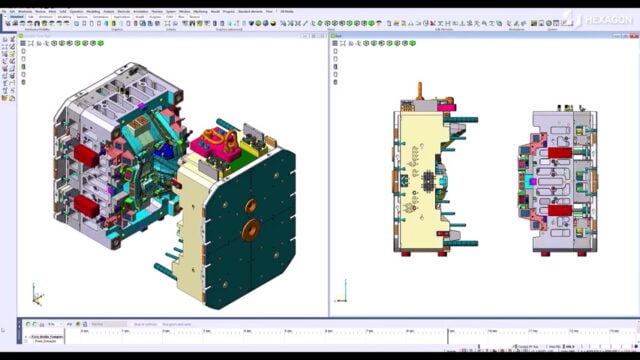

Hexagon’s Manufacturing Intelligence division has unveiled the HxGN Mould & Die, a comprehensive suite of specialized CAD/CAM, engineering, and automation tools designed to empower mould and die manufacturers. This suite aims to streamline operations, reduce costs, and deliver high-quality tools across industries such as automotive and aerospace.

Developed to bolster operational excellence in the design and manufacturing of plastic injection moulds, progressive dies, and similar tools, the HxGN Mould & Die suite offers a range of capabilities. These include CAD/CAE for mould and die design, manufacturing preparation, CNC machine-tool programming, process simulation, G-code verification, and shop-floor production intelligence.

Chuck Mathews, General Manager of Production Software at Hexagon, emphasizes the suite’s ability to leverage Hexagon’s top-notch technologies to deliver superior results quickly. He highlights Nexus, Hexagon’s digital-reality platform, which enhances automation and collaboration opportunities for teams.

Parth Joshi, Chief Product & Technology Officer at Hexagon, views the suite as an exciting development that combines customer challenges with deep domain knowledge to achieve more. He underscores the suite’s role in bringing ecosystem technologies together to help production teams make better-informed decisions faster.

For plastic-injection mould manufacturers, the suite provides tools for design and engineering, flow simulation, reverse engineering, and CNC machining. It builds upon Hexagon’s VISI and WORKNC software, offering comprehensive CAM programming capabilities and supporting the construction and editing of complex 3D geometry.

Reverse engineering tools enable efficient creation of solid models from scanned data, crucial for mould repair and redesign. The suite also offers plastic flow analysis tools to ensure cost-effective and reliable mould production.

For progressive die manufacturers, the suite offers a connected workflow with tools for design, simulation, and production. It facilitates step-by-step unfolding of surface and solid models, providing control over each forming stage.

Overall, the HxGN Mould & Die suite supports shops in maximizing advanced machine tools and optimizing machining cycles. With simulation and verification capabilities, it ensures efficient and error-free CNC programming.

To learn more about the HxGN Mould & Die suite, visit hexagon.com/solutions/mould-die-design-manufacturing.

Original source ASM

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters