Edge Technologies Unveils Six New Bar Feeders and Automation Solutions for CNC Lathes

Edge Technologies is introducing six innovative products designed to enhance CNC lathe operations and streamline production.…

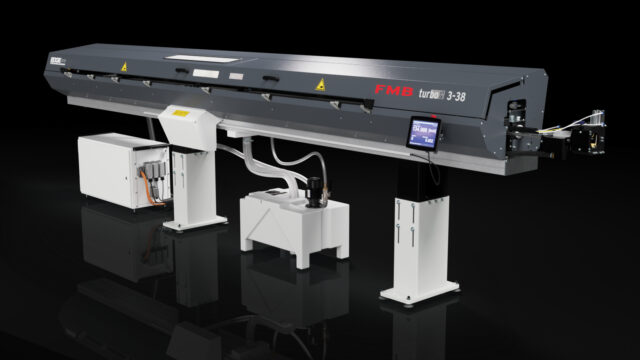

Maryland Heights, MO — Edge Technologies, a leader in magazine bar feeding solutions for the production turning segment, is excited to introduce the FMB Turbo RS 4-45. Newly designed from the ground up, the FMB Turbo RS 4-45 meets the demanding needs of Swiss sliding headstock lathes with diameter capacities up to 42mm.

The Turbo RS 4-45 required FMB to develop their largest extruded machine base yet. This super rigid foundation is the key starting point for a feeder that features RS technology as standard. The patented RS (Revolutionary Sliding) design will take Swiss lathe users to a higher performance level, especially for lathes with longer Z-axis strokes, demanding applications such as non-guide bushing mode, challenging materials, and profiled stock. The integrated and oiled sliding guide module and moving steady rest provide superior bar pusher and stock support in the transition zone between the bar feeder and lathe spindle. FMB’s RS technology eliminates the need for telescopic noses, extended pushers, and Z-axis axial track, all of which minimize the gap between the bar feeder and lathe. The result is reduced vibration, a significant boost to maximum RPM, better surface finishes, and an ability to hold tighter tolerances.

The Turbo RS 4-45 is available with an Auto Adjust capability. Auto Adjust magazine bar feeders are ideal for optimizing CNC turning centers that specialize in short-run work with frequent changeovers over a wide diameter range. The Auto Adjust matches the maximumsized bar pusher to your CNC lathe draw tube or the maximum sized stock. The bar feeder does the rest with a series of aperture-like geared mechanisms that automatically adjust to and support the rotating stock. Change two parameters in the controller, change the bar pusher collet, and you are ready to run a different diameter. You don’t even need to change a spindle liner.

“The combination of FMB’s RS design with the Auto-Adjust feature creates a truly next level magazine feeder, unmatched in optimizing bar stability and achieving Lean throughput,” said Kevin Meehan, President of Edge Technologies. “It’s the kind of lathe automation that will pay for itself in short order while placing a shop in another competitive category.”

Original source Practical Machinist

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters