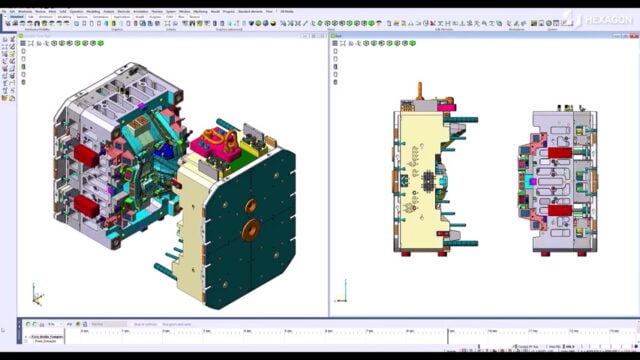

Have you seen these dedicated tools for mould and die?

Mould and die can be a complicated sector to work within. Fortunately, Hexagon has a suite…

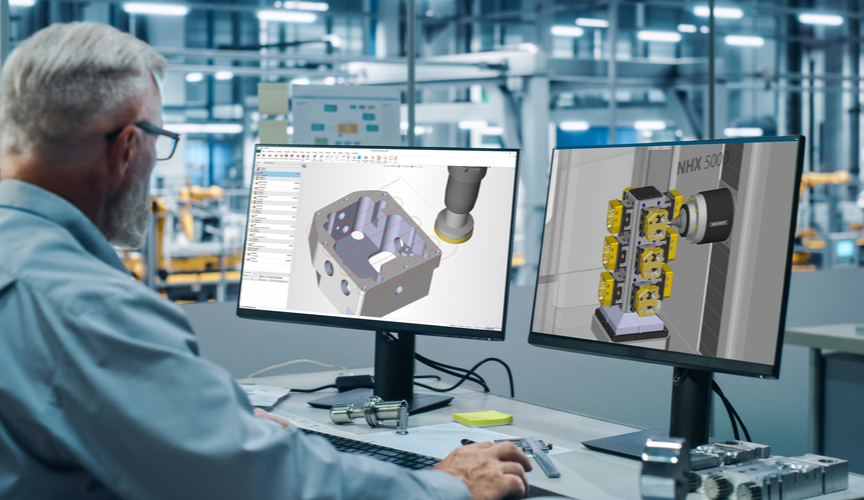

Hexagon Manufacturing Intelligence is showcasing Esprit Edge, an advanced AI-powered manufacturing solution designed to revolutionize CNC machining processes by streamlining workflows and enhancing efficiency. Esprit Edge leverages artificial intelligence (AI) and digital twin technology to optimize cutting strategies, reduce programming times by up to 75%, and improve overall equipment utilization.

Esprit Edge’s AI-driven decision-making capabilities analyze historical data to predict the best machining strategies for each project, continuously learning and adapting to improve outcomes. The system automatically generates machine programs upon loading a design model, eliminating the need for extensive programming expertise and making it easier to upskill existing employees and train new operators.

The core of Esprit Edge is its intelligent optimization engine, which analyzes and optimizes tool paths and machine movements, significantly reducing cycle times and maximizing production output. The system is particularly effective for multi-channel machines, facilitating seamless synchronization and operation. In addition, Esprit Edge enhances tool life, reducing costs and minimizing downtime associated with tool changes.

With Esprit Edge, Hexagon aims to reduce the dependency on highly skilled programmers while empowering the workforce to achieve higher productivity levels. This solution is poised to transform CNC machining, making it more accessible and efficient for manufacturers of all sizes.

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters