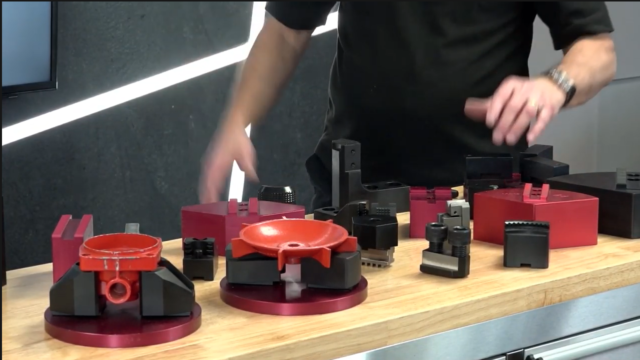

Chuck jaws and vices for every possible workholding requirement

Thame Workholding manufacture the largest range of standard chuck jaws and vices in the country and…

The HWR stamping technology is known to the market as SOLIDStamp, and it is a process in which a defined tooth contour is stamped into the workpiece in advance under high pressure for subsequent clamping by the form fit. This working step takes place outside the clamping device. With #SOLIDStamp from HWR, you create a secure clamping due to established clamping technology. With the help of the stamping station, raw parts can be prepared for clamping in the vice within seconds. Complex pre-machining, such as the milling of clamping points, is no longer necessary. A minimum clamping depth of 3 mm and highest holding forces are only some of the advantages of SOLIDStamp.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters