Tebis 4.1 Release 8 – Flexibility Meets Automation

Tebis CAD/CAM/MES is pleased to confirm that Tebis 4.1 Version Release 8 is now available. The…

Faster processes, simpler operation, greater automation, more flexibility, high quality, improved template technology – Tebis 4.1 Release 5 provides many new and improved functions as well as optimised process flows that will help to reach your goals faster in your day-to-day work.

Overview of benefits:

CAM – Automation

You can change the machining sequence for grouped or cut features with a click of the mouse – without having to break the group or the cut. Programming time is significantly shorter.

Quickly and easily modify NCJobs without recalculating.

Component surfaces, protected surfaces and tools and machines can now be replaced quickly and easily even after NC calculation and all toolpaths are retained. Programming time is significantly shorter.

Machine changes are also possible without recalculation between technology groups or with activated head collision avoidance.

CAM – Milling

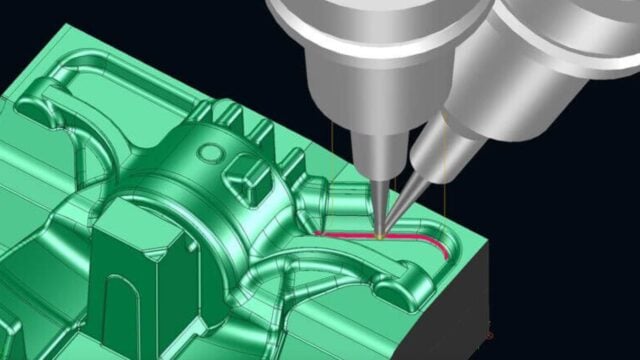

Highly automated and targeted processing of residual stock areas.

The milling areas that will be processed in the subsequent NCJob are automatically transferred. The individual areas are optimally sorted and the optimal connection paths are generated and all completely automatically. Achieve top results without having to intervene interactively a single time.

High-quality 5-axis simultaneous toolpaths for re-roughing with ball cutters can now be quickly and easily programmed: You can create a 3-axis roughing program and then convert it to 5-axis simultaneous machining in “Simultaneous avoidance” mode. The optimal tilt directions are determined automatically. The tool paths are completely collision-checked and the current blank is fully accounted for.

CAM – data processing

High-quality tangential centre curves that are needed for tasks like preparing for laser hardening can now be generated very conveniently and quickly. Manual preparatory work is greatly reduced.

CAM – Drilling

A huge plus for production machining companies: Toolpaths for centering, countersinking, reaming and tapping can now also be programmed with a special turning drilling function. Specific NC cycles are not accounted for in the NC output.

CAM – Lathe

Represent tool references on a 1:1 basis in the tool library.

The options for selecting standard references for turning tools have been greatly expanded. The digital and real worlds are drawing closer together: All references and reference sectors that can be selected in the control are also represented in the digital tool library. Each reference can be stored as a standard reference for the corresponding machining tool.

For CAM programmers, this means greater flexibility and simplified operation: The standard reference is automatically applied to the NCJob. However, the reference can also be subsequently adjusted as needed in the NCJob. The sector can also be specified independent of the cutter geometry for special tools like button tools.

A further major advantage: The tool reference can now also be represented in in the way that the tools are represented in the machine control. The control automatically calculates the resulting tool reference for tilted machining.

CAM – Job planning

The workpiece and clamping devices can be positioned safely and automatically on the machine table based on preconfigured connection points – when clamping electrodes, this even works fully automatically and accounts for the holder. This significantly reduces programming work. Individual elements can be quickly and easily replaced later.

CAD – 3D design

Easily create text with improved user guidance.

The new “Create text as curve” function, can now be used to quickly and easily place text on free-form curves or arcs. The text can be formatted in any way and can also be quickly modified later.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters