Tebis 4.1 Release 8 – Flexibility Meets Automation

Tebis CAD/CAM/MES is pleased to confirm that Tebis 4.1 Version Release 8 is now available. The…

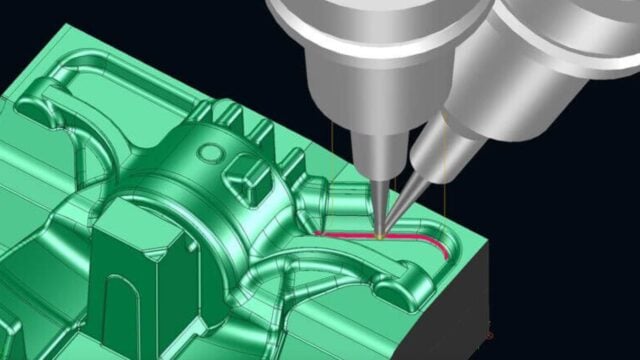

Tebis, a specialist CAD/CAM and MES solution provider, offers its customers a fully integrated solution that detects and resolves potential collisions using digital twins technology in the CAM environment. Tebis has added more features to this well-proven approach in Version 4.1: The option for machine head collision checking is now also fully integrated in the Tebis virtual machine model, along with new functions for 5-axis simultaneous avoidance milling.

Integrated digital twins technology for collision avoidance

The earlier in the process chain that collisions are avoided, the better. Because detecting and avoiding potential collisions at later stage almost always results in unwanted downtime and unnecessary costs,” explains Fabian Jud, Product Manager at Tebis: “Tebis approach is proven and safe: Tebis verifies toolpaths and avoids collisions within the CAM environment. This is achieved by using digital twins of the real manufacturing environment.

The real world machining environment is reproduced precisely in the virtual world by Tebis to ensure that the integrated collision checking functions safely. This includes all geometries – including machines, tool assemblies, clamping devices and limit switches. Tebis completely eliminates simplified substitute geometries: The basis for the NC calculation is usually the accepted machine model. This enables a digital twin of the real NC code to be generated in the CAM environment.

CAM programming with intelligent collision avoidance strategies

Collisions that can be detected while calculating the NC program can be immediately identified and avoided with the appropriate collision avoidance strategies. The most appropriate strategy depends primarily on the specific component geometry, the machining task and especially the available machine. This knowledge should be stored in NC templates. This means that the CAM programmer only needs to select the machine and machining elements. The appropriate collision avoidance strategy – with area reduction, simultaneous 5-axis avoidance milling or indexed machining – is then automatically assigned in each case.

Benefits of the Tebis approach:

* Additional user operation and correction loops are avoided.

* This approach is easier to manage, because the CAM programmer doesn’t need any special knowledge of machine code or other simulation software.

* No manual corrections to the NC code that could place process safety at risk are necessary.

* Planning is easier, because the CAM programmer has access to all the virtual manufacturing components that are represented in virtual digital twin database libraries.

The machine head is fully accounted for in collision checking/automatic area reduction

In the event of potential collisions with the machine head, milling areas are now automatically reduced or excluded from the machining operation in the NC calculation.

Automatic area reduction is generally used in 3-axis roughing: Milling areas that can’t be machined with the tool in use – because of a collision with the machine head, for example – are automatically deactivated.

With the new area reduction, users employ the shortest possible tools for each milling job, which ensures optimal cutting conditions.

The head or table can also be rotated interactively around the C axis during the calculation in the machine kinematics. The benefit is especially clear for asymmetrical heads: The maximum amount of material is removed with the selected tool. Unnecessary residual stock is avoided. The interactive rotations are immediately accounted for in the area reduction.

Additional avoidance milling functions

Given an appropriate machine and control, 3+2-axis programmed toolpaths can also be automatically converted to 5-axis simultaneous toolpaths for collision avoidance. One of the special features in Tebis is that the tool movements can also be controlled interactively with vectors. The user can therefore optimally adapt the cutting conditions to the specific machining situation. The vectors determine the tool tilt direction and pivot movement.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters