Triag Sputnik Workholding by REM Systems is out of this World

MTDCNC’s Tom Skubala is at REM Systems checking out their space age looking workholding. the Triag…

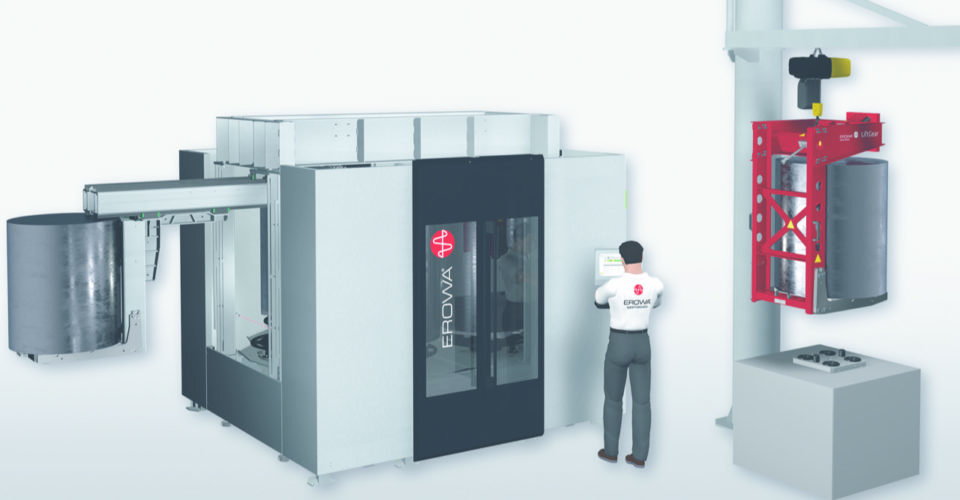

Located in Hall 12 on Stand E83, EMO 2019 visitors can see the new EROWA Robot Easy 800, an automated system that opens up new horizons in machine loading. With this new robot parts up to 850 mm diameter by 1,000 mm long with a maximum weight of 800 kg can be reliably delivered to the machine tools working envelope.

With its wealth of experience based around this technology, EROWA knows that maintaining high productivity of an automated system also requires that the ergonomics need to be taken into account. A central setup station with a swivel crane facilitates the operator’s daily work considerably. Rotatable magazine plates simplify setup and preparation. Pre-centring facilitates pallet positioning with crane and LiftGear.

The stable transfer axis of the robot has a large travel of 3,200 mm, and it can load machine tables between 765 mm and 1,200 mm. It means there is sufficient space for an operator to manually set up any work at the machine tool’s table, if there is a need to ‘break into’ the production run or some special fixturing is required. While the magazine has a 6,400 kg loading capacity within a compact 9 m2 footprint.

All the data required for the production cell is available at a glance, including worklist, magazine loading, tool availability and priorities, via the EROWA process control system. This makes it easy and intuitive to use the Robot Easy 800, even though the size of the parts can be formidable.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters