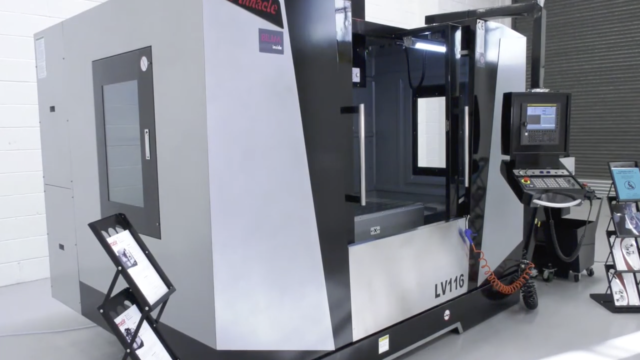

Pinnacle LV116 review with Alan Robinson

In a recent visit, MTD’s resident machine tool expert, Paul Jones took a deep dive into…

Highly productive cost-effective machining has now taken another step forward with the arrival of the new QV Series of machining centres from Pinnacle Machine Tools. With six machines in the range, the QV series offers something for every machine shop.

Like all machines from Pinnacle Machine Tools, the new QV Series has rigidity and stability at its core. This is demonstrated with four slideways that sit upon the Y-axis to fully support the X-axis from the overhanging issue that is so commonplace in many machine tools. Combining this with the compact design, the QV Series offers a particularly small footprint size that can accommodate large and heavy workpieces. All of the major structural parts are manufactured from a high-quality Meehanite cast iron (FC-30), which is stress relieved and aged and all axes are equipped with C3 class pre-tensioned ball screws. Taking this stability a step further, the QV Series has a counter-balance block that moves on a guiding shaft for added stability and better surface finishes.

The boxways on this series are the foundation where stability is built. The box slideways are high-frequency induction hardened to a minimum depth of 2mm with a hardness of over HRc55. Added to this, the contact sliding surfaces are coated and

finely scraped. The machines are available with either a belt-driven ISO40 spindle taper or an ISO50 gear-driven spindle motor. The range is available with Direct drive, belt drive and gear driven spindles with speeds ranging from 6000 to 15000 RPM.

There are six machines in the range and these include the QV117, QV137, QV147, QV159, QV179 and QV209. The smallest of the machines, the QV117 has an X, Y and Z axis of 1140 by 710 by 610mm with the largest QV209 has an X, Y and Z-axis of 2m by 900 by 850mm. The smallest QV117 and the QV137 has an 8000rpm spindle (10,000rpm optional) Up to 15000 as option with larger machines having a high-powered 6000rpm with 8,000 or 10,000rpm Up to 15000 as an option. The numerous models are available with direct drive or gear-driven spindles with a range of speed and torque variants offered. The machines have an automatic tool changer with 24 tool capacity with some models offering the option of a 40 32 tool ATC.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters