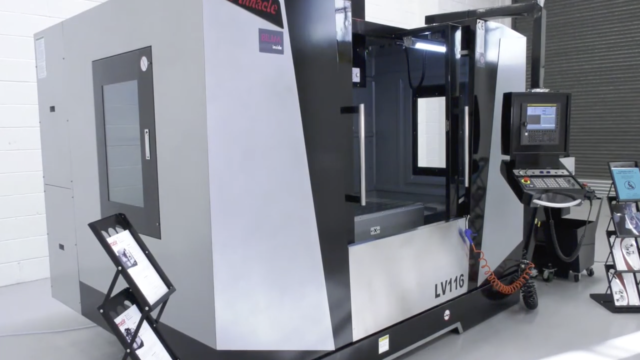

Pinnacle LV116 review with Alan Robinson

In a recent visit, MTD’s resident machine tool expert, Paul Jones took a deep dive into…

For heavy-duty flexible machining, Pinnacle Machine Tools has now introduced its impressive new DV Series of double column machining centres. The robust new machine tools are ideal for machining large-capacity components in the offshore, aerospace, automotive and general subcontract industries.

The new machines incorporate two linear guideways on the cross beam that are arranged in a perpendicular direction to provide optimum rigidity for sustaining cutting forces in the Z and X-axes. The configuration of this structure also allows the motion control on Y-axis to be optimised for smooth and precise kinematic movements.

When considering a large machining centre structural integrity is always a core consideration. With the new DV Series, all major structural parts are manufactured from high quality cast iron that is tempered to relieve stress and ensure maximum material stability without deformation. Additionally, the box type structural parts are rib reinforced to increase structural strength and rigidity and this extra heavy base completely supports the table and resists heavy loads without deformation. The columns and cross beams are made from a single-piece Meehanite casting that offers outstanding support for heavy-duty cutting and this is enhanced by an extra-large contact surface between the column and machine base.

The double-column machining centres are available with an Automatic Head Changer and head storage cabinet and the machine also offers the option of working with a 90° head, universal head or an extension head. The cutting tool changeover can be automatically conducted regardless of whether the spindle is in the vertical or horizontal direction. The machines are also available with a Fork Type (B, C axis) head for 5 face machining and the milling head can also be changed manually. The DV Series is available with four variants, the DV14, DV17, DV19 and DV21. The respective model specifications identify the spacious Y-axis travel of 1400, 1700, 1900, and 2100mm.

The smaller DV14 and DV17 machines are offered with then ISO 40 taper spindle and a powerful 10,000 rpm spindle motor with 12,000 rpm as an option. Up to 15000 on BT40. The larger DV19 and DV21 machines incorporate an ISO 50 spindle taper and a high torque 8000 rpm spindle motor. Up to 12000 on BT50 The extremely capable machines offer X-axis travel from 1.7m to 4.2m with Z-axes travel of 900 (1100mm optional).

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters