HORN ANNOUNCES RETURN OF TECHNOLOGY DAYS

Horn’s Technology Days are back after four years. From 14th to 16th June 2023 at its…

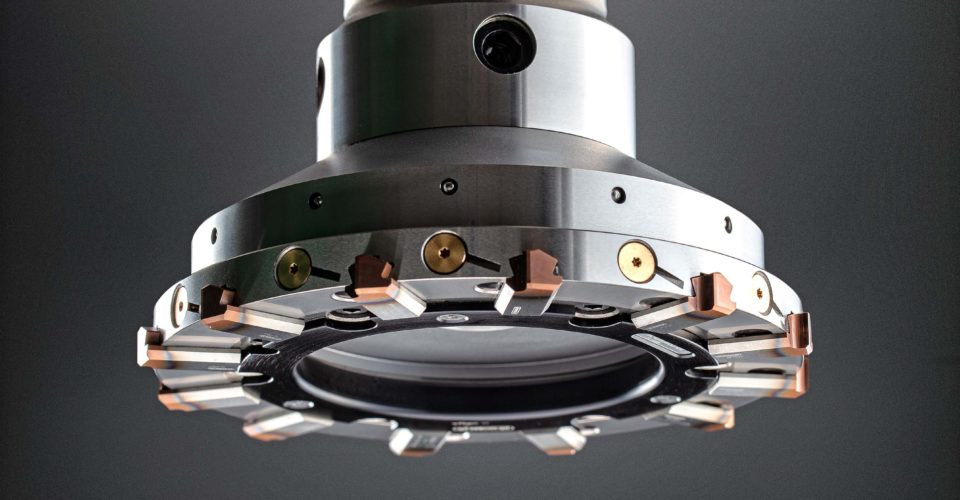

A new, modular system for reaming large diameter holes has been introduced by Horn. Offering high precision, flexibility and easy handling, DR-Large reamers have exchangeable cutter heads with multiple solid carbide inserts, resulting in high cutting values, shorter cycle times and lower costs. The interface of the insert seats has been designed to offer precise interchangeability to within a few microns. Tool setting is unnecessary when exchanging the cutter head.

The versatile, interchangeable reaming system is suitable for bore diameters from 140 mm to 200.2 mm. Six cutter heads cover the range of diameters in 10 mm increments. Two sizes of head fit on each size of reamer shank. Modular construction and an ABS-compatible interface means the tool can be extended to any length, in theory without limit. All reamers are equipped with direct internal coolant supply to each cutting edge.

Reaming is an economical machining process. Compared to boring holes to tight tolerances, it is faster and can significantly reduce unit costs. Until now, reaming tools on the market in these larger sizes have been either special brazed tools or diameter-specific reamers with fixed inserts.

With such tools, which tend to be delicate and heavy, replacing worn inserts is a complex process and calibration can be tricky for many users. Horn offers a practical alternative with its exchangeable-head, pre-calibrated DR-Large reaming tools and its customer service department offers quick and simple reconditioning.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters