TVS Motor Appoints Gaurav Gupta as President of India Operations!

In a strategic move to strengthen its market presence, TVS Motor Company has appointed Gaurav Gupta as President of India Operations.…

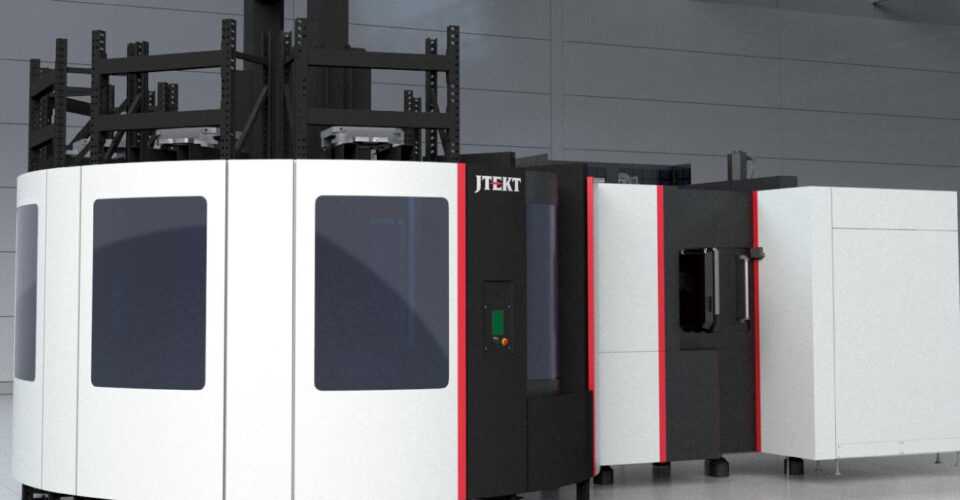

JTEKT Machinery Americas Corp. is proud to present its cutting-edge lineup of seven metalcutting machines and automation solutions, alongside Internet of Things (IoT) technologies and informative technology presentations. The company’s extensive offerings include horizontal machining centers, the WELE five-axis vertical machining center (VMC), vertical turning centers, Takisawa Taiwan CNC turning centers, and two production cylindrical grinding machines.

One of the highlights is the FH5000 Series high-speed horizontal machining centers (HMC) equipped with advanced pallet automation. This includes a pallet pool designed for flexible machining system operation. According to JTEKT, the FH5000 machines deliver 25% more machining capacity compared to other machines in their size category.

The FH5000S-i model features X, Y, and Z strokes of 800 × 800 × 880 mm, a workpiece diameter capacity of 900 mm, and a workpiece height capacity of 1,100 mm. The series also includes a 500-mm table capable of handling loads up to 1,000 kg.

To enhance unattended production capabilities for shops of all sizes, JTEKT designs and manufactures pallet changers for single machines and pallet pools for flexible machining systems, ensuring longer running times and increased efficiency.

Standard features of JTEKT machines include adaptive control, allowing users to manage tool life within acceptable spindle load ranges. The machines, controls, and pallet automation systems are all designed and built by JTEKT to function cohesively.

The FH5000S HMCs, with a 60-tool ATC capacity, are engineered for speed and production reliability. They feature a high-acceleration spindle with specifications of 15,000 rpm, 50 hp (37 kW), and 303 Nm (223 ft-lbs.) of torque. Larger machines in the FH5000 series are equipped with a 50-taper spindle, 60 tools, and extended X-axis travel.

These machines also include a direct drive B-axis table with an index time of 0.7 seconds for 90-degree rotations. The compact design of the FH5000 series allows for more aggressive machining in limited spaces.

Additionally, the FH5000 series is equipped with the Toyopuc Touch panel, which enables operators to monitor the machine, view operating data including energy consumption, and make necessary edits with ease.

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters