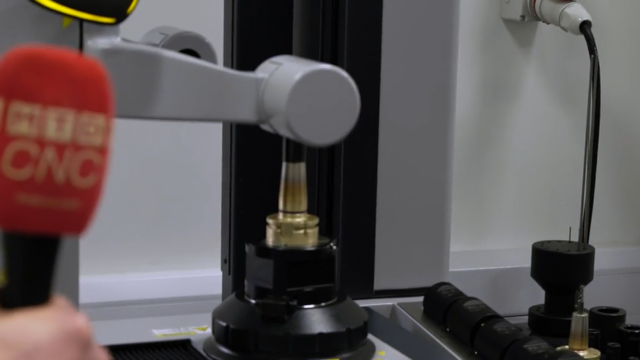

Zoller Redomatic 400, Tool Heat Shrinking, Presetting & Measuring all on one Machine

The Redomatic 400 from Zoller allows quick, easy & accurate tool heat shrinking processes with a…

Lyndsey Vickers from MTDCNC and Chris Andrews from SYS Systems as they discuss FDM technology on the Stratasys F900 and its nearly 18% savings on both costs and time. FDM or Fused Deposition Modelling is a 3D printing technology that uses layer-by-layer deposits of melted material on thermoplastic polymers. Customers from small businesses and OEMs use this technology to 3D print thousands of parts on the Airbus 350. The result is high quality production parts through a reliable and repeatable process. From inner workings of the actual components to moisture control, moving heads, and heat control; a combination of technologies and the MTConnect software are used for making such precise parts. The 3D printing system is highly beneficial for the aerospace industry where we see high volume, low production for a range of applications. MTConnect offers live data feedback of various parameters and the ability to move away from expensive mould tools. Find out how the F900 and other models replace traditional tooling for light weight parts that are quicker and easier to manufacture, allowing better assembly, automation, and operator use. If you have a project in mind, contact SYS Systems at the Carfulan Group.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters