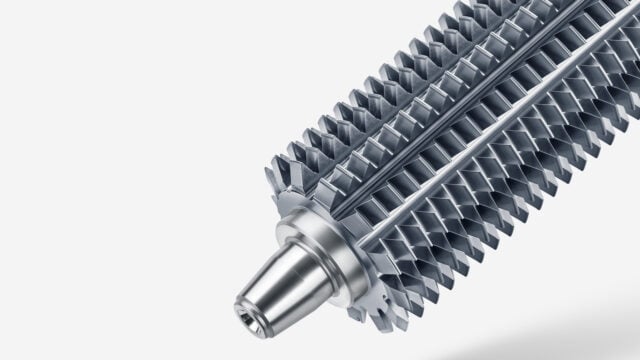

Monaghan Tooling Group Introduces High-Performance Vergnano Hobs!

Monaghan Tooling Group has launched its new range of Vergnano solid-carbide and high-speed steel hobs, specifically…

Davi Inc. has introduced the iVision laser radius measuring system, a cutting-edge solution that integrates artificial intelligence (AI) with its e-Power fully electric machines. Designed to streamline and automate the plate rolling process, the iVision system enhances precision, efficiency, and operational simplicity, making it possible for shops to run machines unmanned.

Key Features of the iVision System

Once the iVision system measures a radius, it transmits the data to the e-Power machine’s CNC, which makes the necessary side roll adjustments in real-time. This level of automation drastically minimizes the need for operator intervention and enhances the machine’s overall productivity.

For shops using machines without CNC controls, Davi offers the iRadius version. This variant provides a digital readout of measurements, enabling operators to manually adjust the machine settings as needed. Both systems eliminate the need for operators to manually measure radii at the front of the machine or inside large parts, improving safety and reducing downtime.

The iRadius unit is fully retrofittable to existing machines, making it a valuable addition for shops handling extremely large parts that traditionally require cumbersome manual measurements. By integrating these systems, manufacturers can optimize their workflows while ensuring superior results.

Davi’s iVision and iRadius systems exemplify the next generation of plate rolling technology. With enhanced automation, reduced operator dependency, and significant time savings, these solutions empower manufacturers to achieve higher productivity and precision while meeting the evolving demands of modern fabrication.

Stay up to date with the latest industry news and events.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters