Over twenty-five years of partnership for these global tech leaders

Automation, multitasking, and one-hit machining – that’s where Nakamura-Tome and Engineering Technology group are innovating together…

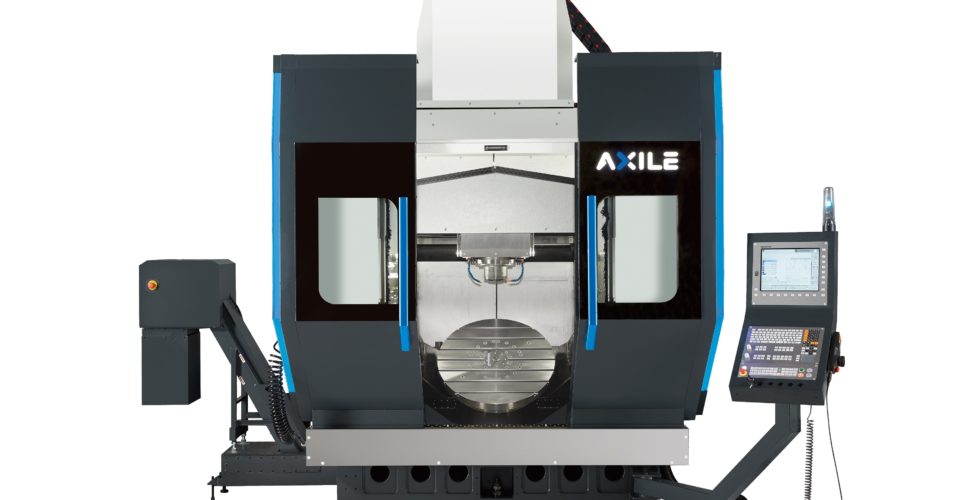

As the UK’s premier supplier of high-technology machine tools, the Engineering Technology Group (ETG) is now introducing the new G8 machining centre from AXILE. Since entering into an agreement with AXILE to be the exclusive UK and Ireland technology partner, ETG is already enjoying a significant level of enquiries for the extensive range of high-end 5-axis VMCs, heavy-duty double-column machining centres and mill/turn machine tools.

The AXILE G8 has a powerful gantry design that perfectly balances rigidity and precision, which is ideal for the machining of complex workpieces. With a maximum loading capacity of up to 1,300kg on a swivelling rotary table, the agility of the G8 enables the production of a wide range of large components. Also in the G8 Series is the G8 MT. This machine option offers both milling and turning in one machine, greatly increasing operational flexibility, reducing set-up times and offering the potential to efficiently machine a wider variety of parts in a single set-up.

The flexibility of the AXILE G8 and G8 MT is built upon a high-quality cast base that offers a structural foundation that optimises vibration damping and limits thermal behaviour. The machine has a chip disposal unit integrated directly under the table and a huge U-shaped closed gantry design that slides along two symmetrical axes to optimise accessibility and stability. From an agility perspective, the AXILE G8 and G8 MT have direct driven servo motors, double symmetrical and synchronised axes and linear scales with a 0,1μm resolution as well as double roller type linear guideways – all features that minimise backlash, vibration and elasticity to optimise precision and performance.

From a specification perspective, both the G8 and G8 MT offer a table size of 800mm diameter with X, Y and Z axes of 670 by 820 by 600mm with a maximum feed rate of 60m/min. The swivelling A-axis moves to +/-120 degrees with a 360-degree continuous C-axis. As standard, the built-in spindle is a 20,000rpm asynchronous motor that is supplied tools from two tooling carousels that present 32/64 position tool change. It can also be equipped with larger magazines up to 120 positions

For the G8 MT mill/turn variant, the rotary A-axis swivels at up to 100rpm whilst the rotary speed of the C-axis can reach up to 1000rpm for turning. Based on unique torque motor technology, the A and C-axes are driven by powerful 20.4 and 55kW motors that provide a remarkable level of speed and dynamics. Both variants of the machine are also available with the option of Heidenhain, FANUC or Siemens CNC and of course the groundbreaking ART Monitoring System.

This digital platform from AXILE is undoubtedly a system that demonstrates how technologically advanced the brand is. The ART Monitoring System delivers agile smart machining that enables 24/7 automated production and allows operators and key decision makers to digitally manage processes by monitoring all wear components, energy consumption and fluids such as lubricant and coolant, supplying real-time status updates on the machine and its components. AXILE’s ART™ empowers manufacturers to make informed decisions, optimising operations and greatly improving production efficiency. The ART™ Interface is available with remote access and usable via any portable devices such as laptop, tablets and mobile phones.

Customers can specify the machine to suit their exact requirements with a choice of CNC control, spindle, tool carousel capacity, chip conveyors, tool and workpiece measurement and much more. For further details, contact your local ETG representative.

Be first to see all the updates from MTDCNC

Our newsletters frequency varies dependant on content

All the latest deals from the industry feature on our newsletters